The Right Dust Collection System to Combat Air Pollution and Global Warming

Industrial activities are an integral part of modern life. Manufacturing, energy, chemical, food, metal, construction and many other industrial sectors form the basis of the world economy. But an inevitable by-product of these industrial activities are emissions and pollutants that can damage the environment. Air pollution from industry has an increasing negative impact on global warming and the environment.

Industrial Air Pollution

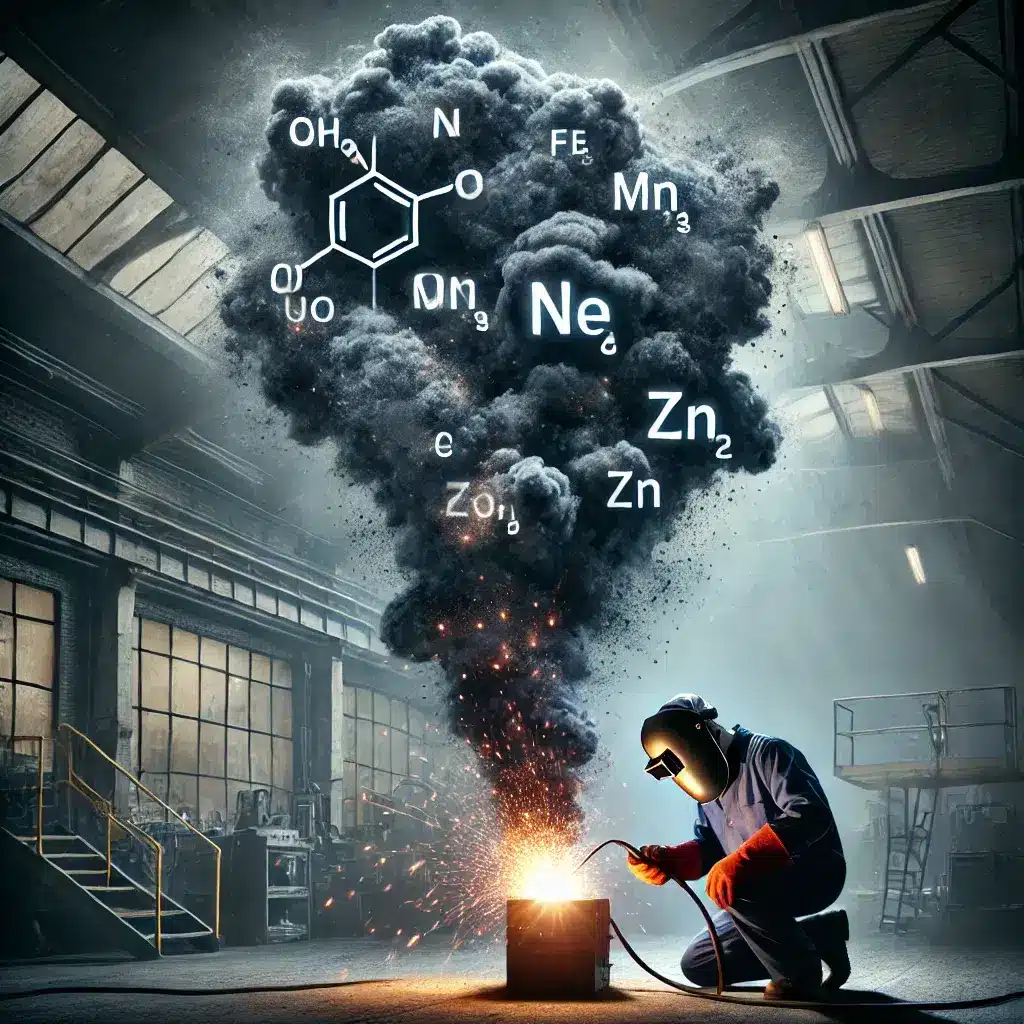

Industrial air pollution comes from a variety of sources, such as the combustion of fossil fuels, smoke from production processes and chemical emissions. Pollutants in the air, such as particles, sulphur dioxide, nitrogen oxides and carbon dioxide, can adversely affect not only the environment but also human health. According to the World Health Organisation, air pollution causes millions of premature deaths every year. Therefore, effective solutions are needed to reduce air pollution in industrial plants.

Global Warming and Industrial Emissions

Global warming is associated with an increase in temperatures worldwide due to greenhouse gases accumulating in the atmosphere. Industrial emissions are one of the largest sources contributing to global warming. Chemical, metal, plastic and other fine dust particles released during production processes in industrial plants also pollute the atmosphere and cause climate change.

These fine dust particles can directly harm the environment and human health. These pollutants released into the atmosphere can disturb the energy balance in the atmosphere by reflecting or absorbing sunlight, causing global temperatures to rise. The effects of global warming include serious consequences such as melting glaciers, rising sea levels and extreme weather events.

Industrial dust can also cause problems such as acid rain. Metal and chemical dusts react with sulphur dioxide and nitrogen oxides in the air to form acidic compounds. These acidic compounds can fall to the ground with rain and damage water resources and soil. Industrial activities are thus associated not only with air pollution, but also with water and soil pollution. Therefore, in the fight against global warming it is important to focus on all pollutants caused by industrial activities and to use effective dust collection systems.

ExPulse and Sustainability

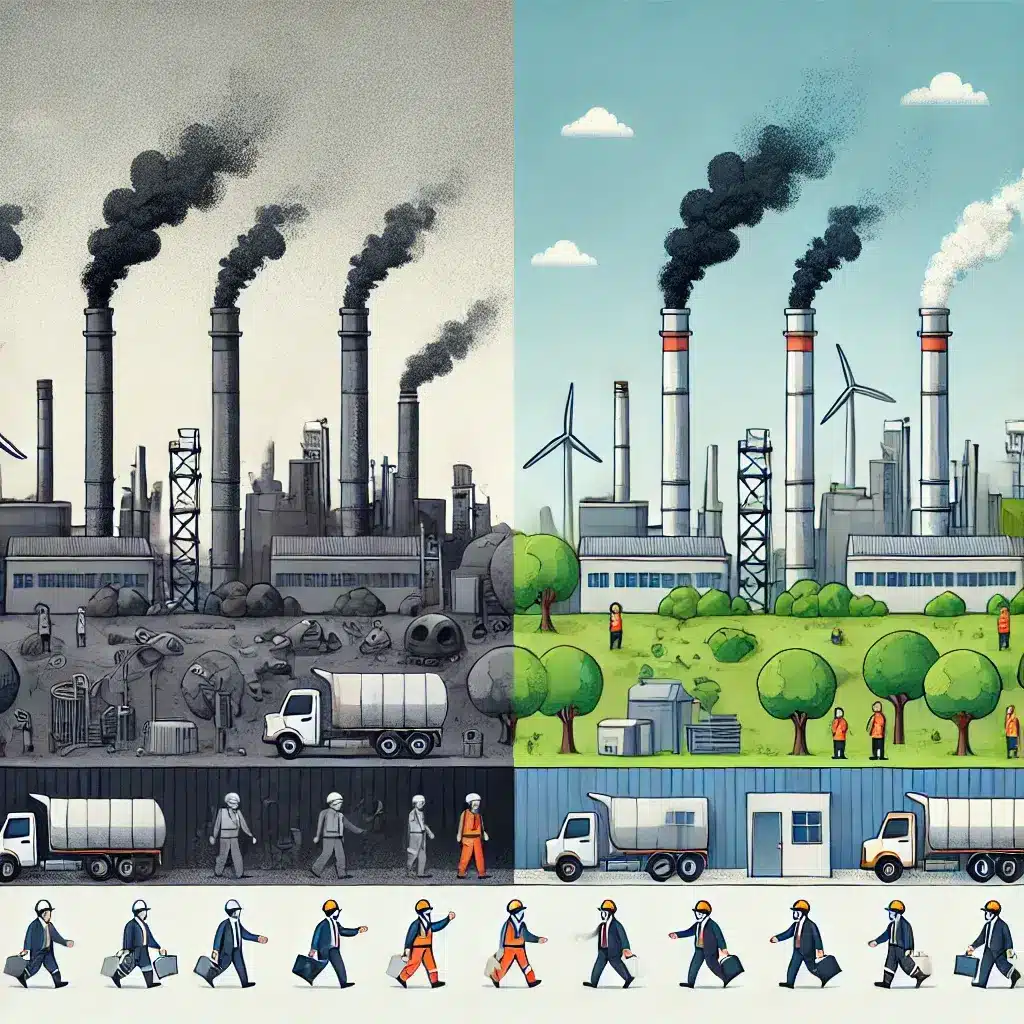

Industrial dust collection systems are one of the effective ways to reduce air pollution and promote environmental sustainability. ExPulse brand develops innovative dust collection technologies to reduce environmental impact in industrial facilities. The company’s sustainability-focused approach helps to mitigate global warming by reducing industrial emissions. ExPulse dust collection systems improve air quality and minimise environmental pollution by reducing particulate matter emissions in industrial facilities.

ExPulse develops environmentally sensitive systems in line with its sustainability goals. The company focuses on technologies that increase energy efficiency, reduce waste generation and lower carbon emissions. Such systems help industrial facilities play an active role in combating air pollution and global warming.

Environmental Benefits of Industrial Dust Collection Systems

Industrial dust collection systems not only reduce air pollution, but also offer advantages in areas such as energy efficiency and occupational safety. These systems clean the environment by effectively capturing polluting particles in industrial plants.

In addition, dust collection systems can improve the energy efficiency of industrial facilities by reducing energy consumption. More efficient systems reduce carbon emissions by reducing the use of fossil fuels. This is an important step in the fight against global warming. ExPulse helps industrial facilities achieve environmental goals with technologies that provide energy efficiency and support sustainability.

ExPulse helps industrial facilities achieve their sustainability goals with its environmentally friendly technologies. The company offers environmentally friendly solutions by significantly reducing particulate matter emissions thanks to the advanced filtration technology used in dust collection systems. This both enables businesses to reduce environmental impact and contributes to improved air quality.

Factors Affecting the Selection of an Environmentally Friendly Dust Collection System

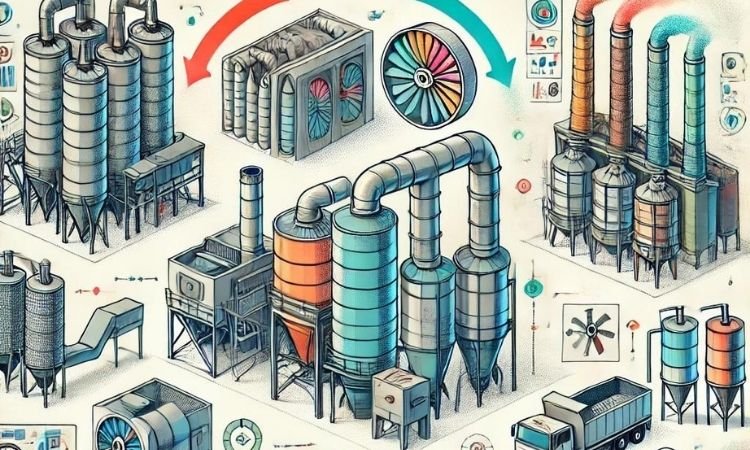

There are many factors to consider when selecting a dust collection system. These factors include the type of dust, industrial processes, environmental regulations and other technical requirements.

1. Dust Type: When selecting a dust collection system, it is important to determine the type of dust generated in industrial processes. Different types of dust, such as metal, chemical, plastic or organic dusts, may require different systems and filters. The size, density and stickiness of the dust should also be considered.

2. Volume and Flow: The dust collection system must be capable of handling the total dust volume and air flow rate generated in industrial processes. Systems with insufficient capacity can increase the risk of air pollution. To select the correct flow rate and volume capacity, it is important to accurately determine the amount of dust and air flow in the production process.

3. Filtration Efficiency: The efficiency of the filters determines the effectiveness of the dust collection system. Cartridge filters, bag filters can be used as well as high efficiency filters such as HEPA (High Efficiency Particulate Air) and ULPA (Ultra Low Particulate Air) are effective in capturing industrial dust. Industrial standards and local regulations should be considered to select the appropriate filter type.

4. Energy Efficiency: The energy efficiency of dust collection systems is important in reducing operating costs and environmental impacts. Energy efficient motors, control systems and fans can optimise energy consumption.

5. **Local and International Regulations: Dust collection systems must comply with local and international environmental regulations. When selecting a system, air pollution and environmental standards should be considered.

6. Work Safety: Dust collection systems and other components must be selected in accordance with work safety regulations. When working with explosive dust, it is vital to use explosion-proof systems and filters. Systems must be selected in accordance with occupational health and safety standards;

7. Maintenance and Durability: Regular maintenance and durability of dust collection systems are important. Durable materials and easy maintenance requirements should be preferred for the long life of the systems. Filter replacement and cleaning procedures should be simple.

8. System Design and Layout: The dust collection system must fit the layout of the industrial plant. The layout of the system should optimise airflow and ensure operational efficiency.

9. Innovation and Technological Advances: Innovation in dust collection systems can improve efficiency. High-tech systems can help reduce the environmental impact of industrial facilities. Systems incorporating technologies such as IoT and automation should be preferred;

10. Waste Management: Waste accumulated in dust collection systems should be managed in an environmentally sound manner. Appropriate strategies should be developed for recyclable waste and hazardous waste should be disposed of safely. Waste management improves environmental sustainability.

11. Cost Effectiveness: When selecting a dust collection system, cost effectiveness is an important factor. The purchase, installation and operating costs of the systems should be taken into account. Energy efficiency and longevity increase cost effectiveness.

12. Multipurpose Use: The dust collection system must be able to adapt to different industrial processes. Systems suitable for multi-purpose use increase the flexibility of businesses. Interchangeable filters and adjustable air flow systems can be preferred for different dust types.

13. Sound Level and Noise Control: The sound level should be at a certain level when dust collection systems are operating. It is important to control sound levels in terms of occupational health and safety. Dust collection system sound levels should be evaluated when making system preferences.

14. Environmental Sustainability: Dust collection systems should support environmental sustainability. Systems that reduce carbon emissions and provide energy efficiency contribute to the creation of environmentally friendly industrial facilities. It is very important to select systems that promote environmental sustainability.

15. Brand and Manufacturer Reliability: When choosing a dust collection system, brand and manufacturer reliability is important. Reliable brands offer quality and durable systems. The manufacturer’s customer service and technical support should also be considered.

Industrial dust collection systems play an important role in the fight against air pollution and global warming. ExPulse develops sustainable technologies to help industrial facilities achieve environmental goals. The company’s innovative systems keep air pollution under control by improving energy efficiency and reducing environmental emissions. The proliferation of such systems will play an important role in preventing global warming and environmental degradation by increasing the sustainability of industrial sectors. ExPulse will continue to help industrial facilities protect the environment with its environmentally sensitive technologies and sustainability-oriented approach.