Green Transformation in Industrial Facilities: The Most Effective Way to Reduce Your Carbon Footprint

The concepts of green transformation and carbon footprint in the industrial sector have become more important than ever. As part of the fight against climate change, governments and international organizations are requiring industrial enterprises to reduce their carbon emissions. Since heavy industrial facilities account for a large portion of total greenhouse gas emissions, transformation in this area plays a critical role in achieving global sustainability goals. A carbon footprint refers to the total amount of greenhouse gases released into the atmosphere, directly or indirectly, as a result of an organization’s activities. Reducing this footprint is essential not only for environmental protection but also for ensuring business continuity and gaining a competitive advantage in the future.

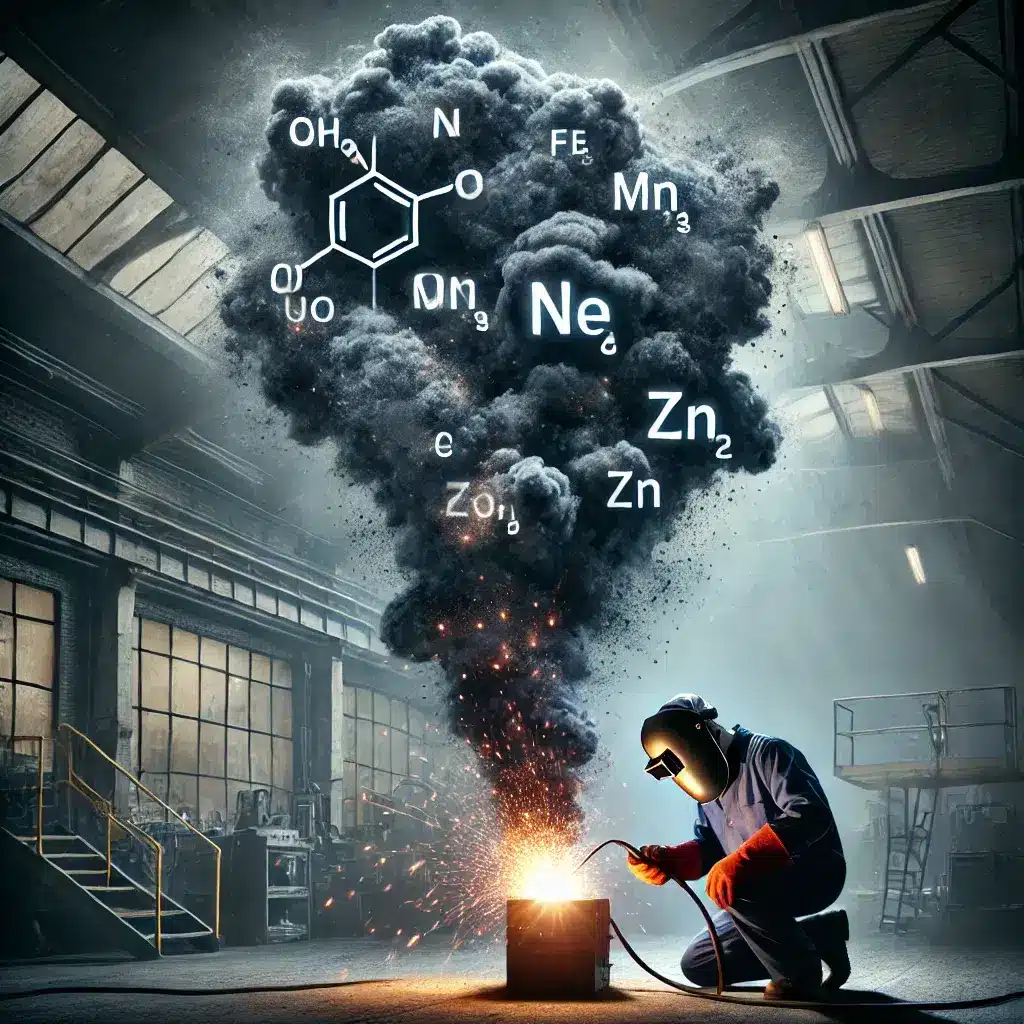

Green Solutions by Expulse Systems: Dust, Fume, and Gas Extraction Systems

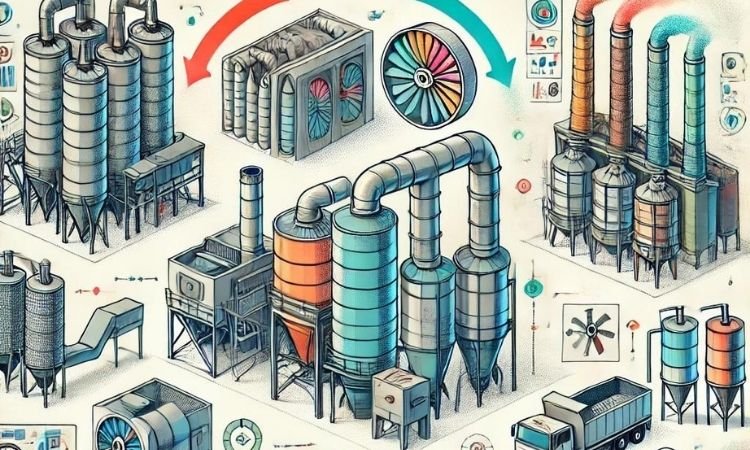

One of the leading technologies that support green transformation in industrial facilities is efficient dust, fume, and gas extraction systems. Expulse Systems offers innovative extraction solutions that help industrial enterprises meet environmental standards and reduce their carbon footprint. The company’s products and services capture and filter pollutants and gases at the source during production, protecting employee health and minimizing the facility’s environmental impact. Key solutions offered by Expulse Systems include:

Central and Mobile Extraction Systems

Expulse Systems designs both portable mobile units and central collection systems that serve the entire facility, tailored to different scales and needs. Central systems collect dust and fumes from multiple machines or processes through a shared duct network and transport them to a single high-capacity dust collector. This centralized approach not only simplifies maintenance and control in large facilities but also enhances energy efficiency. Studies have shown that using one high-capacity central dust collector instead of many small collectors significantly reduces overall energy consumption and carbon emissions. This improves operational efficiency while reducing environmental emissions. Mobile extraction units, on the other hand, are ideal for flexible or temporary needs on production lines. For instance, portable fume extractors can be easily positioned wherever needed within a facility to instantly capture local pollutants.

High Energy Efficiency Designs

Expulse Systems’ solutions are developed with high energy efficiency principles. The systems use fans and motors equipped with inverter (variable speed) drives that can adjust speed according to demand. This smart control technology reduces motor speed when extraction demand is low, preventing unnecessary energy consumption. For example, when the dust load on the filters decreases, the system automatically lowers fan speed to save electricity. In modern dust collection units, pressure sensors and automation also optimize filter cleaning (such as jet pulse) processes; cleaning only occurs when necessary, without frequent stops and starts. As a result, the same task is accomplished using much less energy compared to traditional systems, leading to reduced electricity bills and lower indirect carbon emissions. Ultimately, energy-efficient dust collection technologies help businesses reach their sustainability goals while reducing operating costs.

Ex-proof (Explosion-Proof) Equipment

When designing dust and gas extraction systems, safety and environmental risks must be considered. In environments with a risk of combustible dust or gas explosions—such as flour, coal, metal dust, or chemical vapors—equipment must be ex-proof (explosion-proof). Expulse Systems offers system solutions equipped with explosion-proof fans, motors, and filter housings that comply with ATEX regulations. These ex-proof designs significantly reduce spark-related explosion risks that can occur when combustible dust or gases accumulate. For example, in a grain processing facility, features like spark arresters, automatic fire dampers, or explosion relief panels can be integrated into the system to ensure worker safety and prevent potential environmental disasters. This safety-focused approach also supports occupational health and safety, which is a key part of sustainable production.

High-Efficiency Filtration Technology

Expulse Systems’ dust and fume extraction systems include advanced filtration elements that capture particles at maximum efficiency. Depending on the application, HEPA or nanofiber filters, electrostatic filters, or cyclone pre-filters may be used. For example, in a paint shop facility where ultra-fine dust is generated, a central dust collector with HEPA filters can capture particles as small as 0.3 microns at over 99% efficiency. This ensures that emissions from the facility’s stack remain well below legal limits. High filtration efficiency results in cleaner air output and improved air quality within the work environment. Additionally, using equipment like cyclones for pre-filtration separates larger particles in the first stage, reducing the load on the main filter and extending filter life. This means fewer filter replacements, reducing both waste and operational costs.

Custom Engineering and Flexible Project Design

One of the biggest advantages of Expulse Systems is its ability to provide custom-engineered systems tailored to the unique needs of each industrial facility. Every production process and layout is different. Accordingly, a standard off-the-shelf dust collection unit may not provide sufficient efficiency or safety. Expulse Systems conducts on-site assessments and designs tailored solutions in line with customer needs, including duct layouts, fan capacity, and filter selection. For example, in a facility with limited ceiling height, a specially designed low-profile filter housing can be used. Or in a process with high humidity, moisture-resistant filters and corrosion-resistant materials can be preferred. These customized solutions increase the overall performance of the system, enhance safety, and extend equipment life. This ensures a more sustainable and long-term return on investment (ROI) for industrial enterprises.

Contribution to Circular Economy and Waste Management

Expulse Systems also supports the principles of the circular economy. Waste collected through dust and fume extraction systems—such as raw material residues, recyclable dusts, or chemical by-products—can be recovered and reused. This both prevents waste and reduces raw material consumption. For example, in a metal processing facility, fine metal dust collected from cutting and grinding processes can be recycled and reintroduced into the production process. Similarly, in a plastic production plant, collected plastic dust and granules can be reintegrated into production. These applications reduce both environmental impact and operational costs. In this context, Expulse Systems not only focuses on pollutant removal but also offers equipment that facilitates waste separation and reuse.

A Healthier Work Environment and Social Responsibility

Beyond environmental and economic benefits, dust and fume extraction systems also offer critical advantages in occupational health and safety. Airborne dust and fumes can lead to serious respiratory diseases, allergies, and long-term health problems among employees. The use of effective extraction systems ensures cleaner and safer indoor air quality. This boosts employee morale, reduces health-related absenteeism, and increases productivity. Moreover, companies that invest in employee health and environmental sustainability strengthen their image in society and among customers. Expulse Systems contributes to the social responsibility of enterprises by creating safe and healthy work environments that support both human and environmental well-being.

Conclusion: A Key Step for a Sustainable Future

Green transformation is no longer just a trend but a necessity. Industrial facilities aiming to reduce their carbon footprint and transition to more sustainable operations must invest in efficient dust, fume, and gas extraction systems. With its advanced technology, customized solutions, and commitment to occupational and environmental safety, Expulse Systems helps businesses reduce environmental impacts while enhancing performance. Those taking firm steps toward the future today will gain a competitive edge in the sustainable economy of tomorrow.

References

- European Commission. (2020). A European Green Deal. https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en

- European Commission. (2023). Carbon Border Adjustment Mechanism (CBAM). https://taxation-customs.ec.europa.eu/carbon-border-adjustment-mechanism_en

- Republic of Türkiye, Ministry of Trade. (2023). Report on the European Green Deal and Its Reflections on Türkiye. https://ticaret.gov.tr

- PwC. (2022). ESG Reporting Guide 2022. https://www.pwc.com/gx/en/services/sustainability/publications/esg-reporting.html

- McKinsey & Company. (2023). The Net-Zero Transition: What It Would Cost, What It Could Bring. https://www.mckinsey.com/business-functions/sustainability/our-insights

- TÜSİAD – Turkish Industry and Business Association. (2022). Carbon Border Adjustment Mechanism and Its Impact on Turkish Industry Report. https://tusiad.org

- Ellen MacArthur Foundation. (2021). Completing the Picture: How the Circular Economy Tackles Climate Change. https://ellenmacarthurfoundation.org

- Republic of Türkiye, Ministry of Environment, Urbanization and Climate Change. (2022). Guide for Reducing Industrial Emissions. https://csb.gov.tr

- IEA – International Energy Agency. (2021). Energy Efficiency 2021. https://www.iea.org/reports/energy-efficiency-2021

- IPCC – Intergovernmental Panel on Climate Change. (2022). AR6 Climate Change 2022: Mitigation of Climate Change. https://www.ipcc.ch/report/ar6/wg3/

- Turkish Standards Institution. (2023). TS EN ISO 14001: Environmental Management Systems – Requirements with Guidance for Use. https://www.tse.org.tr

- ISO. (2023). ISO 50001: Energy Management Systems — Requirements with Guidance for Use. https://www.iso.org/iso-50001-energy-management.html

- TÜBİTAK MAM – Scientific and Technological Research Council of Türkiye, Marmara Research Center. (2022). Industrial Dust Collection Systems and Energy Efficiency Report. https://mam.tubitak.gov.tr

- VDMA – Mechanical Engineering Industry Association (Germany). (2023). Efficient Extraction Systems in Industrial Production. https://vdma.org

- TÜRKONFED – Turkish Enterprise and Business Confederation. (2021). Green Transformation Guide for SMEs. https://turkonfed.org